Greeneville, TN - We are currently in a new

era of ATV racing. The popularity of competition ATV’s

has elevated factory involvement and support to the highest

level ever. The demand is there, and the manufacturers know

it. The big four have been controlling the technological advancement

of racing ATV’s since the 80’s, only making enough

improvements to keep the market going. Consequently, their

two-wheeled machines have progressed to the point where you

can buy a competitive bike off the showroom floor and race

it with only minor modifications, whereas the quads offered

require a substantial investment to be competitive. Without

a serious threat to the all-Japan market, ATV’s would

be doomed to wallow in a low-tech world.

Enter the 2008 Can-Am DS450

|

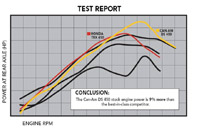

Horse

Power Comparsion Chart |

The DS450 is not a redesign of an existing machine. The

design of this quad was done from the ground up by a group

of engineers starting with a clean slate. Each part was

reevaluated, and if there was a better way to do it, it

was done. The result is a machine that has more radical

design changes than any ATV since they decided to add another

tire onto the three wheelers. The fuel injected Rotax engine

is based on technology developed with World Championship

caliber four stroke road race engines. The intake valves,

bore, and throttle body are the largest of all the Sport

450’s, and the potential to modify the engine is massive.

This powerplant was designed with the capability to be modified

far past its already class-dominating performance level.

| |

|

| The

CanAm DS450 Powerplant is a Rotax 4-TEC 450 EFI Engine

with the top end based on the Aprilia RSV 1000 R sportbike

with its free-flow intake design with dual sparks

plugs. The piston bore, intake valves, and throttle

body is the largest among the 450cc Sport ATVs.

|

|

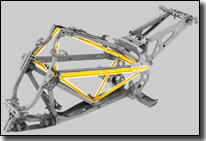

Altec

aluminum frame with its dual-pyramidal frame design

|

The chassis of the DS450 utilizes construction techniques

previously unheard of in the industry. The aluminum frame

is a combination of cast, extruded, and stamped pieces joined

with aerospace-grade fasteners that eliminate any strength-reducing

welds. You heard it right, a frame with no welds at all.

Parts of the frame are removable for servicing, and sections

can be replaced and reattached with conventional fasteners

to get the machine back on the track in an emergency. The

dual-pyramidal frame design is exceptionally strong, and

the designers were able to fine-tune the structure without

the guesswork of weld-area weakness, resulting in the lightest

frame in its class. The frame weight helps put the DS450

at 345 lbs dry, which is lighter than all other 450’s

with or without EFI.

| |

|

| The

CanAm DS450 Altec aluminum frame utilizes an aluminum

lock-bolt fastener system along with conventional

nuts and bolts to connect the forged and stamped aluminum

frame components instead of a conventional welding

method |